INTRODUCTION

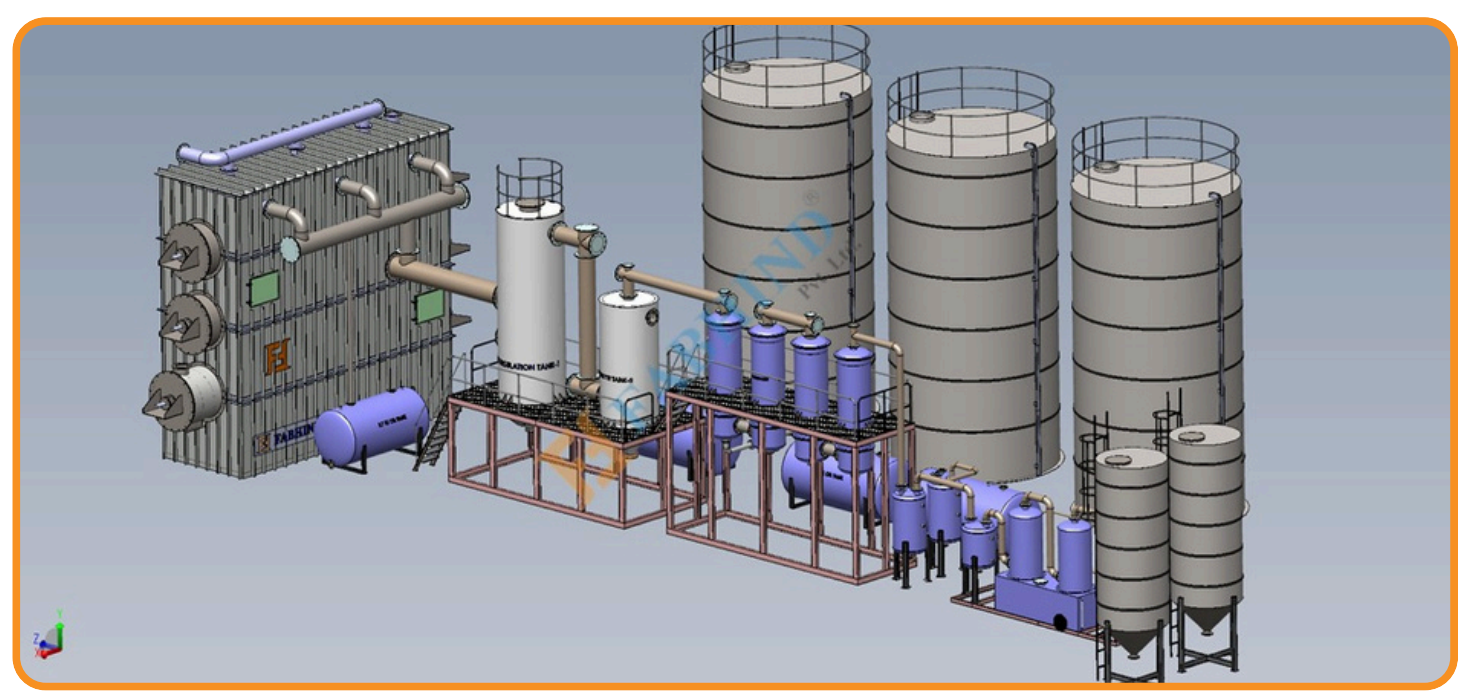

The Whole Project Is Composed Of the Whole Project Is Composed Of 30 TPD Continuous Waste Tire Pyrolysis Plant:

TECHNICAL SPECIFICATION

| NO. | ITEM | SPECIFICATION | |

|---|---|---|---|

| 1 | Model | Waste Tyres / Chips Continuous Plant | FAB - 30 |

| 2 | Capacity | Tons Per Day | 30 TPD |

| 3 | Power | Total Power | 100 HP |

| 4 | Working Type | Continuous | |

| 5 | Reactor Design | Continuous Reactor Vertical Type | 3 Reactor |

| 6 | Rotating | Internal Screw Type Rotating | 3 Reactor |

| 7 | Cooling System | Recycled Waste Cooling | |

| 8 | Reactor Material | BQ 516 - 70 Grade & SS 304 | |

| 9 | Heating Method | Direct Hot Air Heating | |

| 10 | Heating Fuel | Fuel Oil & Gas | |

| 11 | Feedstock | Waste Tyres / Chips 5 to 25 MM | |

| 12 | Output | Fuel Oil, Carbon Black |

ADVANTAGES OF FAB CONTINUOUS PYROLYSIS PLANT :

- Our Reactor Has 360 Degree Outside Rotating System Which Allows It To Heat Proper Way So It Has Long Life

- Spiral Flats Are Designed In To The Reactor Which Helps Running The Material By Its Inner Wall. The Raw Material Direct Contacted With The Heat Transfer Surface And Received Immediate Heat And Evenly Distributed

- The Reactor And Feeder System Adopts Frequency Drive (VFD) To Adjust The Retention Time Of Raw Material In The Reactor According To The Pyrolysis. It Can Decompose In Minimum Time To Increase High Oil Yield.

- Reactor Can Be Loaded By Steel Wire Free Tire Chips And It Can Also Separate The Carbon Black From Hair Steel Wires At The Time Of Carbon Discharge. It Has Hair Steel In Wires It Can Be Collected By Hair Steel Magnet Separator Machine. Hence It Will Be Collected Directly To The Carbon Bags If It Doesn’t Have Hair Steel In It

- Gas & Oil Burner Can Be Used For Extra Flue Uncondensed Gas For Secondary Heating Process Of The Pyrolysis Reactor, Which Will Reduce Production Cost And Customer Revenue. The Flue Gas After Combustion Is Treated By Dual Wash Scrubber System As Per Environment Standards. Ii Is Using Evaporated Flue Gas For Heating Process Of Reactor, Where We Recycle Extra Heat For The Process.

ADVANTAGES :

- Our Reactor Has 360 Degree Outside Rotating System Which Allows It To Heat Proper Way So It Has Long Life.

- Spiral Flats Are Designed In To The Reactor Which Helps Running The Material By Its Inner Wall. The Raw Material Direct Contacted With The Heat Transfer Surface And Received Immediate Heat And Evenly Distributed.

- The Reactor And Feeder System Adopts Frequency Drive (VFD) To Adjust The Retention Time Of Raw Material In The Reactor According To The Pyrolysis. It Can Decompose In Minimum Time To Increase High Oil Yield.

- Reactor Can Be Loaded By Steel Wire Free Tire Chips And It Can Also Separate The Carbon Black From Hair Steel Wires At The Time Of Carbon Discharge. It Has Hair Steel In Wires It Can Be Collected By Hair Steel Magnet Separator Machine. Hence It Will Be Collected Directly To The Carbon Bags If It Doesn’t Have Hair Steel In It

- Gas & Oil Burner Can Be Used For Extra Flue Uncondensed Gas For Secondary Heating Process Of The Pyrolysis Reactor, Which Will Reduce Production Cost And Customer Revenue. The Flue Gas After Combustion Is Treated By Dual Wash Scrubber System As Per Environment Standards. Ii Is Using Evaporated Flue Gas For Heating Process Of Reactor, Where We Recycle Extra Heat For The Process.