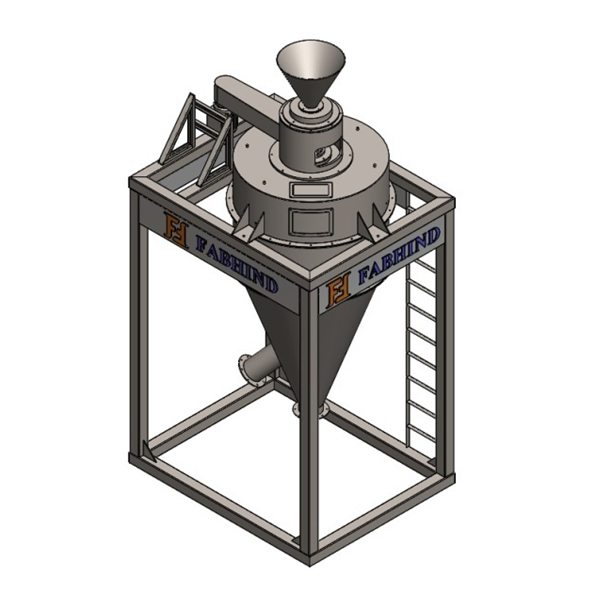

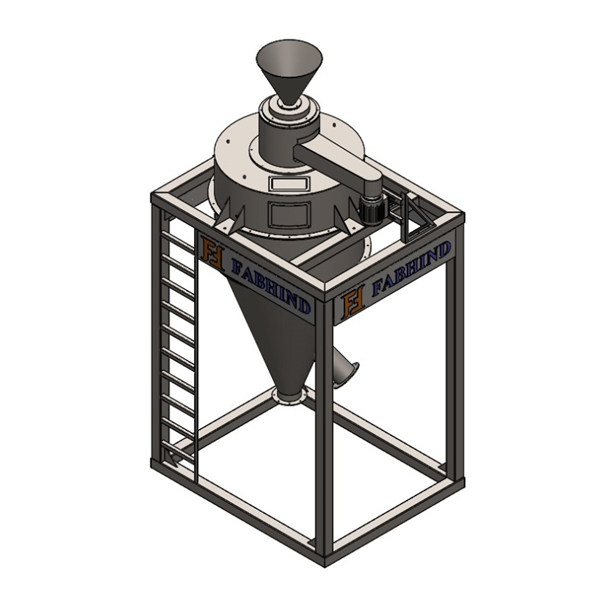

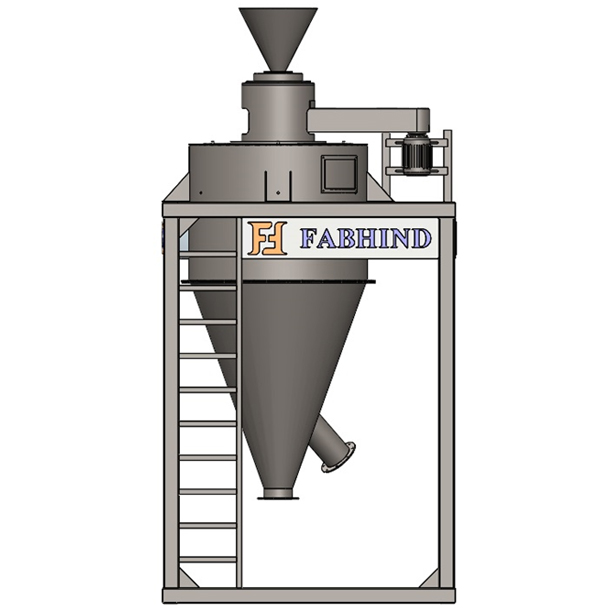

CENTRIFUGAL AIR CLASSIFIERS

FABHIND Company whirlwind centrifugal air classifiers are machines for separating fine material from coarse material with a usual fin-product range of from 40 to 400 mesh. Their accuracy in selecting the desired fine product is amazing

As they are built in many sizes from 20” to 24’ in diameter with capacities from a few hundred pounds to over a hundred tons per hour, a size may be selected to give practically any desired tonnage.

The FABHIND Company whirlwind centrifugal air classifier is essentially a sizing machine, a classifier or a selector. It does not crush nor reduce material, but is a carefully designed apparatus for sizing, by separating the fine material from the coarse.

It is efficient when operated alone or in a closed circuit with most types of grinding machines. Ground materials from the Mills are conveyed to the Air Classifier for particle size selection. The finer particles (fines) are selected for use or storage and the coarser particles rejected and may be returned to the Mill for further grinding.

They may be used for the removal of fine particles (dust) from materials already milled or in a natural fine state, but their most important function is to operate in closed-circuit with a pulverizer.

In “Closed-Circuit” grinding the air classifier becomes an important and integral part of the pulverizing system and the governing factor of the finished product.

“Closed-Circuit” allows both Mill and air classifier to function as each was designed to function; the one to grind, and grind only, without handicap or hindrance, and the other to select and remove the finished product from the pulverizer, easily, freely and as soon as made. This has been a real accomplishment of modern science availed of by many who have understood and appreciated its possibilities.

The modern slow-speed durable FABHIND Company whirlwind centrifugal air classifier has truly revolutionized the pulverizing technique. It has not only been the means of materially reducing grinding costs by increasing mill capacities from 25 to 300 %, lowering power consumption from 10 to 50%, and decreasing upkeep, but has greatly improved efficiencies and made possible finer, and still finer products to meet ever more exacting trade requirements.

Its capacity is almost unlimited, and its ability to handle enormous circulating loads is unequaled. A 16’ Separator, for example, is taking a feed of 8 tons per hour containing an only small percentage of the desired product and is delivering 3 tons per hour of material 90% 200 mesh. Only a few years ago such a circulating load was unheard of, such a capacity unbelievable, such an efficiency unknown, yet today it is thoroughly practical, many times desirable and economical.

The principle of FABHIND Company whirlwind centrifugal Air Classification is simple. It consists of the exact regulation and control of the centrifugal force and air currents, one counteracting and overbalancing the other to such a nicety that by simple adjustments a product of almost any desired fineness is selected and collected, while the coarser sizes are rejected. The efficiency of operation depends upon the reliable accuracy of these adjustments. And although the principle is simple it has been a most difficult matter to work out practically.

We are always at your disposal to provide you with all the original spare parts for your Air Classifiers provided by us and according to the original plans that we have.

FEATURES

Utilizing our in-depth industrial knowledge and modern technology, we are manufacturing a premium range of Air Classifiers that are used for processing in following areas :

Mineral & Others

- Chemical Technical Products

- Dyestuffs

- Pigments Colors

- Fertilizers

- Metal Separation

- Insecticides / Pesticides

Features & Advantages

- Particles are reduced to finer and more uniform sizes.

- Use of cyclone separator leads to less dusting on output side.

- No dusting from feeding hopper because feeding is done under negative pressure.

- It runs at lower speed , hence it requires much less maintenance.

- They are easy to clean & wash.

- It is manually fed as normal practice & can be supplied with automatic feeding as well.

- It uses air classification which does not require screen. Hence, it is free from problems like conking, printing & frequent replacement of screen do not arise.

Air classifier Features:

- Strong construction of mechanism and casing ensures long life

- Close control over product uniformity

- Special liners are available for processing abrasive materials.

- Particles are reduced to finer and more uniform sizes.

- Use of cyclone separator lead to less dusting on output side

- No dusting from feeding hopper because feeding is done under negative pressure

- It runs at lower speed, hence it requires much less maintenance

For More Information Contact Sales Dept

TECHNICAL SPECIFICATION

|

FABHIND WHIRLWIND CENTRIFUGAL AIR CLASSIFIERS |

Production Kg. / Hr |

Mash |

HP |

|

FAC-75 |

130 to 200 Kg. |

Up to 325 Mash |

7.5 HP |

|

FAC-100 |

200 to 250 Kg. |

Up to 325 Mash |

10 HP |

|

FAC-125 |

300 to 400 Kg. |

Up to 325 Mash |

12.5 HP |

|

FAC-150 |

400 TO 600 Kg |

Up to 325 Mash |

15 HP |

ASPHALT DRUM MIX PLANT